Vacuum Technology and Vacuum Design Handbook for Accelerator Technicians This handbook is a compilation of information gathered from over 50 years of direct hands-on experience to applicable information widely available from the vacuum technology industry.

VACUUM SYSTEM DESIGN A.G. Mathewson CERN. Geneva, Switzerland 1 . INTRODUCTION In this paper the basic terms used by the vacuum engineer are presented and some useful formulae are also given. The concept of bakeout is introduced and the physics behind it explained. However we will not dwell on the very basics of vacuum system design but

CHAPTER 3: An Introduction to Vacuum Systems - Geneseo

Chapter 3 describes the general components needed to construct a rough vacuum system: a vacuum chamber, vacuum pump, vacuum gauge(s), valve(s), and fittings. The amount of gas from all sources to be removed from the system is defined as the gas load.

Introduction to Vacuum Technology - Open Textbook Library

2024年3月28日 · This book approaches vacuum systems from a pressure regime viewpoint, covering basic vacuum science, followed by the rough vacuum regime, including gas load, pumping mechanisms, pressure measurement, vacuum system construction, and basic troubleshooting concepts.

Fundamentals of Vacuum | Power & Motion

2024年2月2日 · Knowing how to measure vacuum level and select the right pump technology are some of the basic steps required to design an optimized vacuum system.

Maintaining the quality of the accelerator and beamline vacuum system is essential for the reliable and safe operations of the APS. The scattering of accelerated electrons by residual gases reduces beam lifetimes and

How To Design Vacuum System: Essential Steps For Optimal …

2024年12月22日 · This article explores the significance of vacuum systems in maintaining clean workspaces, details key components like pumps and valves, and outlines crucial design considerations such as pressure ranges and material selection.

Vacuum System Design and Considerations

2023年6月7日 · Designing a vacuum system requires careful planning and consideration to ensure optimal performance and efficiency. Various factors come into play, including the specific application, desired vacuum level, component selection, and system configuration.

Designing a Reliable and Efficient Vacuum System

2018年4月23日 · A vacuum system is made up of more than a pump, and its design is dependent on the application. However, all applications need reliable and efficient designs, so to illustrate how to achieve that, we will focus on two types of applications and systems.

Vacuum System Design

Vacuum System Design is the systematic engineering process focused on creating systems that generate, maintain, and control environments with pressure lower than atmospheric conditions.

Vacuum engineering - Wikipedia

Vacuum engineering techniques are widely applied in materials processing such as drying or filtering, chemical processing, application of metal coatings to objects, manufacture of electron devices and incandescent lamps, and in scientific research.

In accelerator vacuum system design, or/and in accelerator operations, knowledge of vacuum pressure distribution (or profile) is often needed for the following reasons: Optimizing pumping speed and capacity installed to keep average pressure and peak pressure under desirable level

COMPLETE GUIDE TO INDUSTRIAL VACUUM SYSTEMS - IVAC

The term “industrial vacuum” can sometimes be misleading, since what may be labeled a “vacuum system” can actually be a pump system or a configuration of the two. These heavy-duty industrial vacuum systems are designed to use vacuum and pressure to move different materials.

selection of proper type vacuum system, process calculation stages for vacuum systems including capacity, estimation of air leakage and rough estimation of utility consumption and a typical P & I diagram for a vacuum system.

The goal is to develop a numerical model of the vacuum system whether simple or complex. This efforty is undertaken to provide an understanding of the critical issues (e.g. conductance limiting components, surface outgassing rates and leak rates) in order to design the most cost-effective pumping system.

Vacuum Engineering Calculations and Applications

Fluids Systems Design and Engineering. Vacuum is now required for many scientific and industrial purposes, particularly those associated with semiconductors, lighting bulbs, and material-coating industries.

AVS - Vacuum System Design

Learn about the design and fabrication of vacuum systems. This course deals with the principal aspects of system design, including materials selection, fabrication techniques, pump selection, sizing pumps and vacuum piping to a chamber, determining pumpdown time, leak rate specification, and surface preparation procedures.

Particle accelerators, storage rings, nuclear fusion research, and space simulation belong to the most extensive scientific applications of vacuum. The working pressure pW determines the design of a vacuum system.

setup of the vacuum pumps. The study, design, construction and installation of vacuum pumping systems viz. Vacuum chamber, Rotary pump, Roots pump was done. The working of rotary and roots pumps was studied and a list proper and necessary components and accessories was prepared. The methods to calculate

Keys To Applying Vacuum Systems - Design World

2012年10月31日 · In a vacuum system, the difference between atmospheric and vacuum pressure creates the ability to lift, hold, move and perform work. There are two types of systems, porous (or open) and non-porous (or closed). Each has a …

Roborock Saros 10R robot vacuum review: an ultra-capable

4 天之前 · The Roborock Saros 10R is the perfect hybrid robot vacuum for even the most cluttered of homes. With its brand new solid-state LiDAR navigation system, slim sub-8cm stature, excellent suction ...

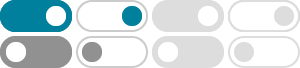

Banish the chaos: Organizing your design system effectively

2025年2月6日 · A design system is a good way to organize your design toolkit. It allows you to keep your UX/UI documents in one place and design your product clearly from start to finish. This enables better efficiency for designers and developers alike. There are different types of design systems. In this article, we’ll go into three structures of design ...